Bambu Lab A1 Common Issues: Things You Should Do Before Any Serious Print

Too low Z Offset / Wrong Temp for PETG

Problem with Z Offset + Temperature + Max Volumetric speed

If your z offset is too far or too close , it could cause the rough surface. Thats why when you need to know how to benchmark the z offset by 0.025 each setting , you can increase the number or decrease it.

========

settings could be ...0.06, 0.04, 0.02, 0, -0.02, -0.04, -0.06...

Filament: PETG

Printing Speed Mode: Luminous

Z Offset: 0.06 / or could decrease by 0.05 if you want to test best fit for more filament

Temp: 265

Max Volumetric Speed: 12 mm3/s

;===== for Textured PEI Plate , lower the nozzle as the nozzle was touching topmost of the texture when homing ==

;curr_bed_type={curr_bed_type}

{if curr_bed_type=="Textured PEI Plate"}

G29.1 Z{0.06} ; for Textured PEI Plate

{endif}Result: Good Print Surface

PLA

Z offset: 0.03

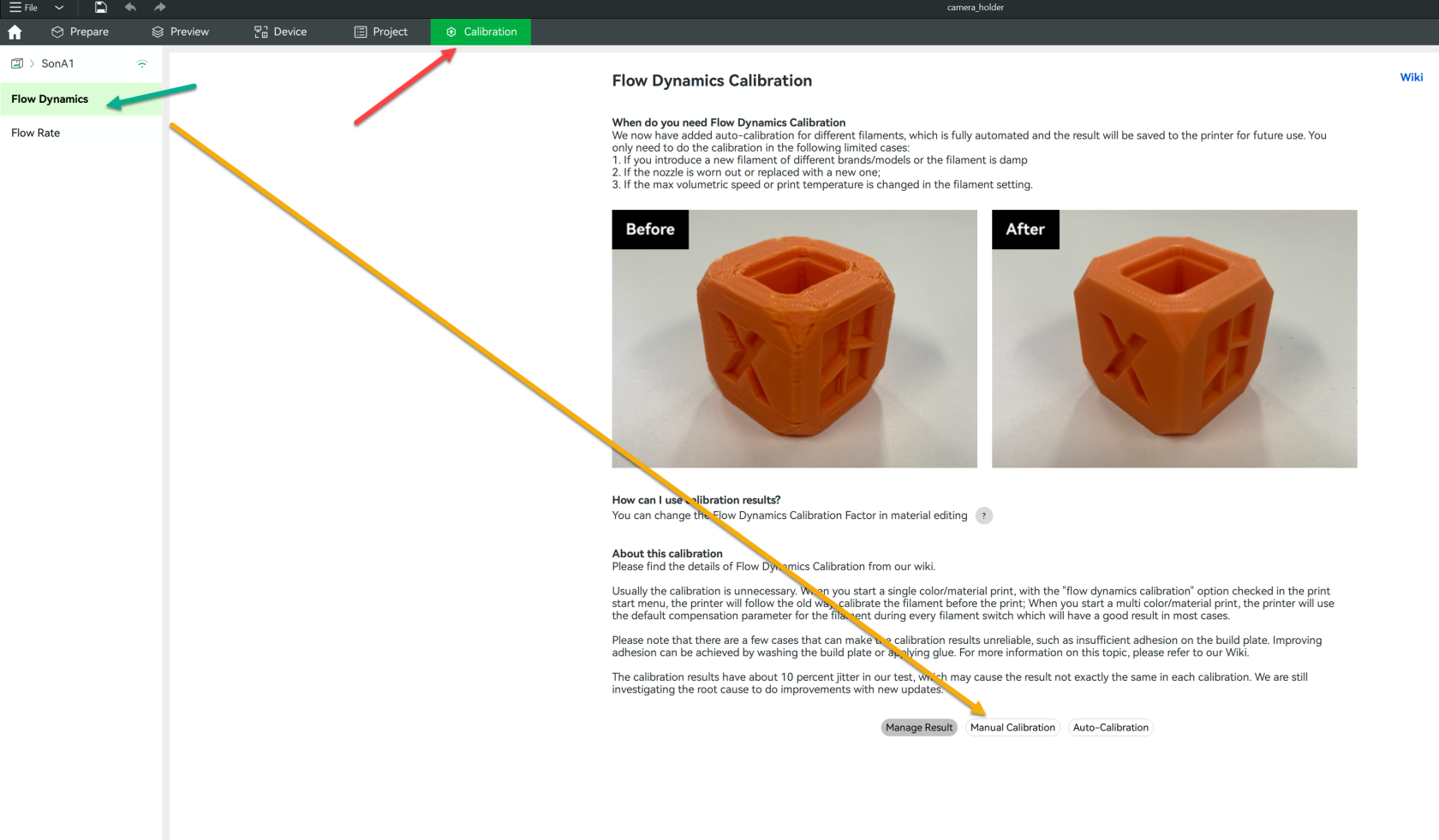

Calibration: Calibrate Your Filament Before Usage

Learn here

Change the K Value to : 0.03 and the value step: 0.001

Pick the best line which has good k factor for the printer

The above are two filament , one wood color filament is PLA on my P1S printer, and one gray color is PETG on A1 Printer.

It's hard to tell the differences between the lines so take a look carefully around 0.02 to 0.018 , you will see the differences between them and other lines. Once you've seen it, please take the value and fill in the Calibration Page on Bambu Studio , and give it a good brand name of the filament to record it and use it in the future.

My choice of K factor of A1 , Petg Filament by Kingroon is 0.03 and PLA filament by Kingroon for P1S printer is 0.019

After you've updated your filament k factor on the device, please proceed to the flow calibration.

Same thing with the flow calibration:

Adjust your flow ratio in the project filament and save it.